Forstilling og bremser

Det kan se ut til at en del av forstillingsdelene er byttet tidligere. Bærearmer er i relativt bra stand slik at armene blir sandblåst og malt, mens alle foringer, ledd og opphengskuler blir byttet.

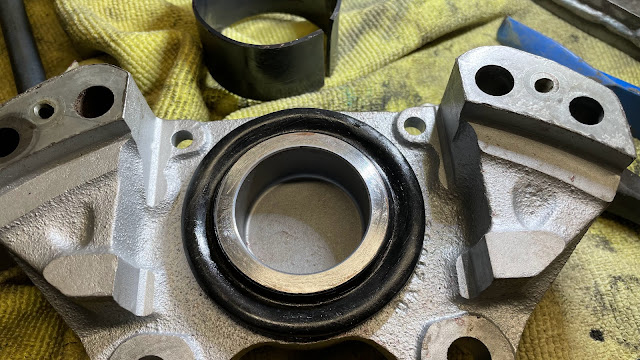

Hullene borres opp til riktig dimensjon (17 mm) slik at det passer til skiven for støtdempergummien.

It looks like that some of the parts were replaced earlier. Control arms are in relatively good condition so they are sandblasted and painted, while all bushings, steering rods and ball joints are replaced.

Godset i tårnet er bra med bare litt overflaterust.

Traversen er stort sett grei, men toppen på støtdemper festet er defekt og må repareres. Dette er en kjent feil på disse bilene. Det blir sveist inn en plate med riktig hull i toppen.

The cross member is mostly fine, but the top of the shock absorber is defective and must be repaired. This is a known fault on these cars. A new plate will be welded in.

Etter demontering blir alle delene sandblåst og malt tre strøk med Bengalack "Rett på rust". Denne blir veldig hard og slitesterk.

After disassembly, all parts are sandblasted and painted with three coats of Bengalack. This becomes very hard and durable.

Så var det bremsene, her har jeg kjøpt inn overhalingssett for caliperne framme. Det viste seg faktisk at selv om bremsene ikke har vært brukt på minst 35 år var fortsatt stemplene løse og minimalt med rust på disse. Veggene i sylindrene innforbi pakningen var helt fri for rust slik at de var absolutt verdt overhaling.

Then it was the brakes, here I bought an overhaul kit for the front calipers. The brakes has not been used for at least 35 years, but the pistons were still loose and there was minimal rust on them. The walls of the cylinders inside the gasket were completely free of rust so they were absolutely worth overhauling.

Jeg måtte lage et enkelt spesialverktøy for å holde gummimansjetten på plass mens stempelet presses inn.

I had to make a simple special tool to hold the rubber sleeve in place while the piston is pressed in.

Stempelet presses da inn inni plastringen.

The piston is then pressed into the plastic ring.

Laget en tilsvarende for de små stemplene.

Made a similar one for the small pistons.

Da var de klar.

Then they were ready.

Så var det å presse i foringer for nedre bærearmer.

Then it was time to press in bushings for the lower control arms.

Toppen på støtdempertårnet er originalt 2 mm plate, men jeg bytter til to stk 2 mm plater der den nederste ligger under med 3 mm overlapp som helsveises rundt kanten. Den andre sveises oppå med punktsveiser og helsveising rundt kanten.

The top of the shock absorber tower is original 2 mm plate, I change to two 2 mm plates where the lower one is under with a 3 mm overlap that is welded around the edge. The other is welded on top with spot welds and welding around the edge.

The steel in the tower is in good condition with just some surface rust.

Platene er klar og sprayes med sveisegrunning.

The plates are ready and sprayed with welding primer.

Nederste plate sveises inn.

The bottom plate is welded in.

Sveisen slipes slik at den øverste platen passer inn.

The weld is grinded so that the top plate fits in.

Ferdig sveist.

Finished welding.

Hele toppen slipes.

The top is grinded.

The holes are drilled to the correct dimension (17 mm) so that it fits the disc for the shock absorber rubber.

Så var det maling i original farge.

Then it was painted in the original colour.

Traversen for disse bilene har litt forskjellig farge, grå på tidlige modeller, men denne har originalt samme farge som resten av bilen (46).

The cross member for these cars has different colours, gray on early models, but this car has originally the same color as the rest of the car (46).

Så er det montering av bærearmer, kuler og spindel.

Then there is the assembly of the control arms, balls and spindle

Fjærer og støtdempere monterer jeg senere etter montering på bilen.

I install springs and shock absorbers later after assembly on the car.

Kommentarer

Legg inn en kommentar